Device/equipment development/demonstration for the full scale practical system research and measurement

R&D efforts (Application development linked to plant applications and actual use)

Ongoing projects

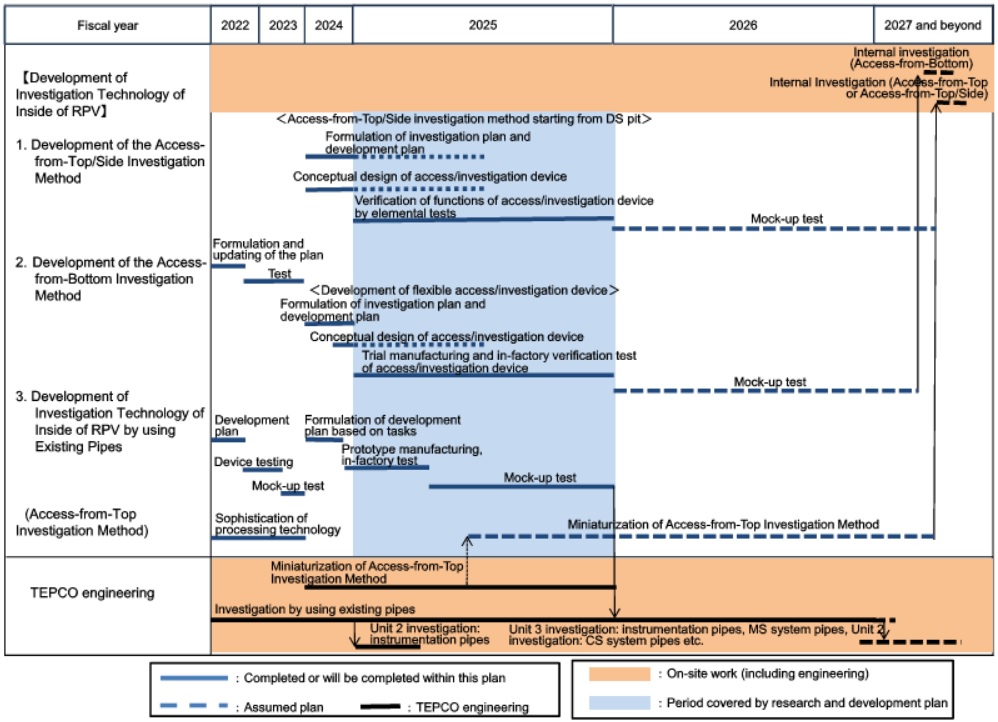

Development of Investigation Technology of Inside of RPV (Project of Decommissioning and Contaminated Water Management)

Summary

In order to contribute to consideration concerning fuel debris retrieval inside of the Reactor Pressure Vessel (RPV), the investigation technology for grasping the situation with fuel debris inside RPV etc. shall be developed.

Action items

- Development of the Access-from-Top/Side Investigation Method

- Development of the Access-from-Bottom Investigation Method

- Development of Investigation Technology of Inside of RPV by using Existing Pipes

Implementation plan

Source: FY 2025 Research and Development Plan for Decommissioning

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 27, 2025 )) (PDF page 4-5)

Results & performance by fiscal year

- FY 2024

- Status of progress at the end of February 2025 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 27, 2025)) (PDF page 47-48 Japanese)

- FY 2023

- FY 2022

- FY 2021

- FY 2020

- FY 2019

- FY 2018

- FY 2017

- Final report (Development of technology for investigation inside the RPV (March 2018)) (IRID) (PDF)

- Status of progress at the end of February 2018 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 1, 2018)) (PDF page 19)

- FY 2016

- Interim report at the end of FY 2016 (Development of technology for investigation inside the RPV (April 2017)) (IRID) (PDF)

- Status of progress at the end of February 2017 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF page 22)

- FY 2015

- Completion report (Development of technology for investigation inside the RPV (March 2016)) (IRID) (PDF)

- Status of progress at the end of February 2016 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 25, 2016)) (PDF page 38)

- FY 2014

Results & performance for individual projects, etc. (Archives)

Switch button

Completed projects

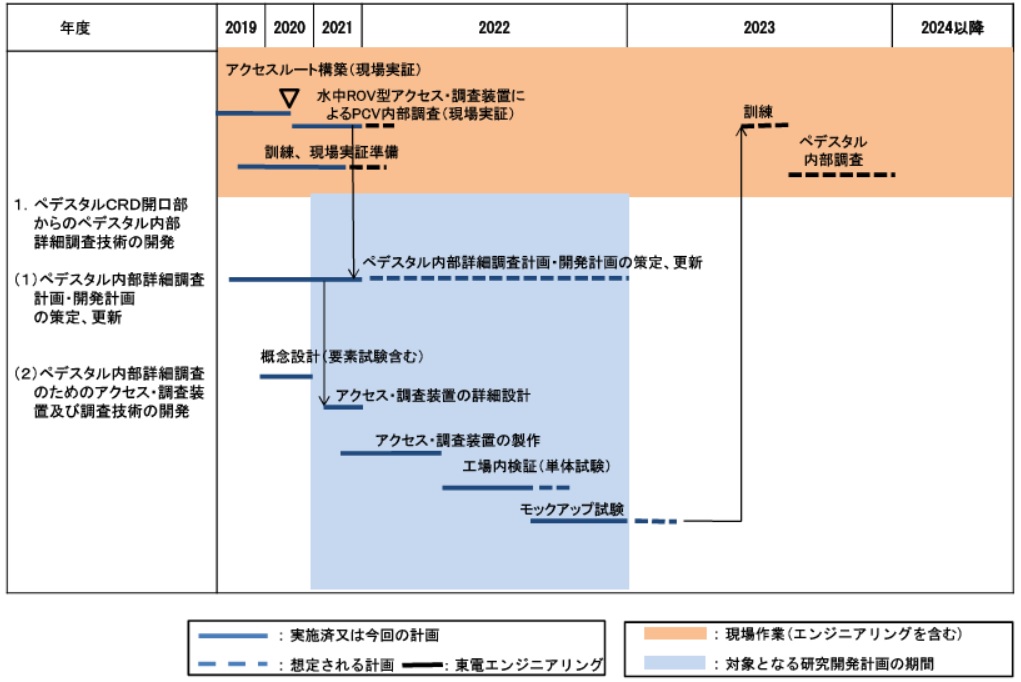

Development of Technologies for In-depth Investigation of PCV Inside (Project of Decommissioning and Contaminated Water Management)

Summary

In order to investigate the distribution of fuel debris in the Reactor Primary Containment Vessel (PCV) and the situation inside and outside the pedestal with higher accuracy than before, we will develop and demonstrate equipment and more advanced investigation technology.

Action items

- Development of detailed investigation technology inside the pedestal from the CRD opening of the pedestal

(1) Formulation / update of detailed investigation plan / development plan inside pedestal

(2) Development of access / investigation equipment and investigation technology for detailed investigation inside the pedestal

Implementing organizations

Implemented by IRID.

Implementation plan

Source: FY 2022 Research and Development Plan for Decommissoning

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (January 27, 2022)) (PDF page 9)

Results & performance by fiscal year

- FY 2022

- FY 2021

- FY 2020

- FY 2019

- Status of progress at the end of February 2020 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 27, 2020)) (PDF page 20)

- Inspection inside Unit 1 PCV through X-2 penetration (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (May 30, 2019)) (PDF)

- Inspection inside Unit 1 PCV through X-2 penetration, work using abrasive water jet (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (April 25, 2019)) (PDF)

- FY 2018

- Development of boat type access investigation equipment with diving function for in-depth investigation of Fukushima Daiichi Unit 1 PCV inside (March 28, 2019) (IRID/Hitachi GE) (PDF)

- Status of progress at the end of February 2019 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 28, 2019)) (PDF page 20)

- Status of progress at the end of February 2019 (On-site Demonstration of Technologies for In-depth Investigation through X-6 Penetration) (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 28, 2019)) (PDF page 20)

- Status of progress at the end of February 2019 (On-site Demonstration of Technologies for In-depth Investigation Considering Measures of Deposits) (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 28, 2019)) (PDF page 21)

- Inspection inside Unit 1 PCV through X-2 penetration (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (January 31, 2019)) (PDF)

- FY 2017

- FY 2017 result report (Development of technologies for in-depth investigation of PCV inside (April 2018)) (IRID) (PDF)

- Status of progress at the end of February 2018 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 1, 2018)) (PDF page 18)

Predecessor project: Development of Investigation Technology of Inside of PCV (Project of Decommissioning and Contaminated Water Management)

Summary

We developed inspection equipment and systems using remote operations to verify the condition inside of the pedestal inside the PCV and performed plant verification, to contribute to retrieval of fuel debris. Also we made the development plan in order to carry out the more in-depth actual unit inspection for fuel debris retrieval, and performed the elemental test.

Action items

- Make and revising inspection/development plans

- Development of access/inspection device and system to specific areas

(1) Inspection inside the pedestal of Unit 2- A2' Inspection: visual inspection of platform bottom

- Visual inspection technology by underwater swimming device

- On-site inspection (on-site validation)

Implementing organizations

Implemented by IRID.

Implementation plan

Source: Progress status of R&D projects and direction for next period

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF page 5)

Results & performance by fiscal year

- FY 2018

- Analysis results of samples, etc. related to inspections inside Unit 1-3 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (July 26, 2018)) (PDF)

- Status of studies on inspection inside PCV, sampling and analysis (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (July 26, 2018)) (PDF)

- Inspection results of inside Unit 2 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (April 26, 2018)) (PDF)

- FY 2017

- Status of progress at the end of February 2018 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 1, 2018)) (PDF page 27)

- Inspection results of inside Unit 2 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 1, 2018)) (PDF)

- Development of inspection equipment of inside Unit 2 PCV (December 22, 2017) (IRID/Toshiba Energy Systems & Solutions Corporation)

- Inspection inside Unit 2 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (December 21, 2017)) (PDF)

- Inspection inside Unit 3 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (November 30, 2017)) (PDF)

- Inspection inside Unit 2 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (November 30, 2017)) (PDF)

- Inspection inside Unit 3 PCV (summary of the news)(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (July 27, 2017)) (PDF)

- Inspection inside Unit 2 PCV (validation result of dose rate)(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (July 27, 2017)) (PDF)

- Inspection inside Unit 1 PCV (analysis result of video data and dose data) (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (July 27, 2017)) (PDF)

- Inspection inside Unit 3 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (June 29, 2017)) (PDF)

- Development of submersible crawling robot to survey inside PCV of Fukushima Daiichi Unit 3 (June 15, 2017) (IRID/Toshiba)

- Inspection inside Unit 3 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (May 25, 2017)) (PDF)

- FY 2016

- Report of results(Development of technology for investigation inside the PCV (April 20, 2017)) (IRID) (PDF)

- Inspection inside Unit 2 PCV - additional report by the image analysis (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 30, 2017)) (PDF)

- Inspection inside Unit 1 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 30, 2017)) (PDF)

- Inspection inside Unit 2 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF)

- Inspection inside Unit 1 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF)

- Status of progress at the end of February 2017 (METI Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF page 22)

- Development of robot “PMORPH” for investigation inside Unit 1 PCV (February 3, 2017) (IRID/Hitachi GE Nuclear Energy)

- Inspection inside Unit 2 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (January 26, 2017)) (PDF)

- Inspection inside Unit 2 PCV (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (December 22, 2016)) (PDF)

- Opening the hole in X-6 penetration for inspection inside Unit 2 PCV and future plans (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (November 24, 2016)) (PDF)

- FY 2015

- Completion report (Development of technology for investigation inside the PCV (March 2016)) (IRID) (PDF)

- Status of progress at the end of February 2016 (METI Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 25, 2016)) (PDF page 37)

- Improved robot for investigation inside the PCV (Scorpion Robot) (February 18, 2016) (IRID/TOSHIBA)

- Development of technology for underground floor inspection outside the pedestal of Unit 1 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (January 28, 2016)) (PDF)

- Training on use of ‘TEMBO’ equipment to remove shielding blocks and iron plates now underway (May 28, 2015) (IRID/MHI)

- FY 2014

- Summary of results (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 26, 2015)) (PDF page 3)

- Ongoing development of “Submergible Crawling Swimming Robot” and “Shape-changing Robot” (April 24, 2014) (IRID)

- FY 2013

- FY 2012

- Summary of results (METI, Secretariat of The Council for the Decommissioning of TEPCO’s Fukushima Daiichi (March 28, 2013)) (PDF page 51)

Results & performance for individual projects, etc. (Archives)

Switch button

- Investigation and development plan

- Technology for access inside the pedestal (A series inspections, verification at Unit 2)

- A1 Inspection: CRD rail status inspection (finished plant verification)

- Result of inspection inside Unit 2 PCV (March 19, 2013) (TEPCO) (PDF)

- Setting up permanent monitoring instruments inside the Fukushima Daiichi NPS Unit 2 PCV, and inspecting inside (March 1, 2013) (TEPCO) (PDF)

- A2 Inspection: Inspection of condition of platform inside pedestal

- [Video introduction] It shows operations training for inspections inside Fukushima Daiichi NPS Unit 2 PCV and equipment for removing accumulations and equipment for advance checking inside the pedestal (October 14, 2015) (IRID)

- Inspection inside Unit 2 PCV, inspection above platform inside pedestal (A2 inspection), study conditions for removal of X-6 shield blocks, and inspection around X-6 (August 27, 2015) (IRID) (PDF)

- Future approach to inspections inside Unit 2 (A2 inspection) (July 30, 2015) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” inspection inside Unit 2 PCV (A2 inspection), and conditions for removal of shield blocks for the X-6 penetration (July 13, 2015) (IRID) (PDF)

- Development of robots for inspection inside Fukushima Daiichi NPS PCV (June 30, 2015) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” A2 inspection inside Unit 2 PCV (regarding X-6 penetration area conditions) (June 29, 2015) (IRID) (PDF)

- Inspection inside Unit 2 PCV (A2 inspection), progress status of removal of X-6 penetration shield blocks (June 25, 2015) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” X-6 penetration shield block removal as part of the local verification test of the inspection above platform inside pedestal (A2 inspection) (May 28, 2015) (IRID) (PDF)

- Development of technology for access to pedestal exterior and plant verification (B series inspections, verification at Unit 1)

- B1 Inspection: Inspection of condition above grating on pedestal exterior first floor

- “Development of technology for investigation inside the PCV” - Development of inspection technology for Unit 1 pedestal below ground floor - (January 28, 2016) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” Results of onsite verification test of inspection above grating of pedestal exterior first floor (B1 inspection) (April 30, 2015) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” Results of additional check of onsite verification test of inspection above grating of pedestal exterior first floor (B1 inspection) [Portion implemented April 18, 19] (April 20, 2015) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” Implementation of onsite verification test of inspection above grating of pedestal exterior first floor (B1 inspection) [April 16, 2015 flash report portion] (April 17, 2015) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” Implementation of onsite verification test of inspection above grating of pedestal exterior first floor (B1 inspection) [April 15, 2015 flash report] (April 16, 2015) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” Implementation of onsite verification test of inspection above grating of pedestal exterior first floor (B1 inspection) [Portion implemented April 10] (April 13, 2015) (IRID) (PDF)

- “Development of technology for investigation inside the PCV” Implementation of onsite verification test of inspection above grating of pedestal exterior first floor (B1 inspection) (March 26, 2015) (IRID) (PDF)

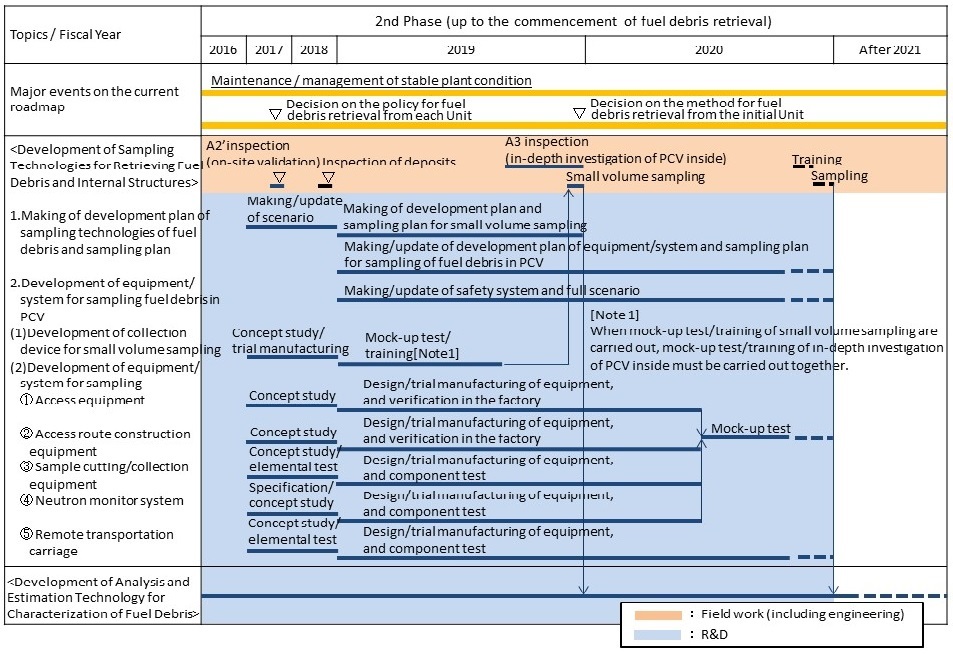

Development of Sampling Technologies for Retrieving Fuel Debris and Internal Structures(Project of Decommissioning and Contaminated Water Management)

Summary

We develop technologies of sampling of actual fuel debris, to contribute to criticality control, equipment design and rationalization of construction procedure for the construction of fuel debris retrieval.

Action items

- Making of development plan of sampling technologies of fuel debris and sampling plan

- Development of equipment/system for sampling fuel debris in PCV

(1) Development of collection device for small volume sampling

(2) Development of equipment/system for sampling- Access equipment

- Access route construction equipment

- Sample cutting/collection equipment

- Neutron monitor system

- Remote transportation carriage

Implementing organizations

Implemented by IRID.

Implementation plan

Source: FY 2019 Research and Development Plan for Decommissioning

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 28, 2018)) (PDF page 10)

Results & performance by fiscal year

- FY 2019

- FY 2018

- FY 2017

- FY 2017 result report (Development of Sampling Technologies for Retrieving Fuel Debris and Internal Structures (April 2018)) (IRID) (PDF)

- Status of progress at the end of February 2018 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 1, 2018)) (PDF page 25)

Fuel Debris Detection Technology (Using Muon) (Project of Decommissioning and Contaminated Water Management Finished/suspended December 2015)

Summary

It is important to understand the location and amount of fuel debris inside the reactor for 1F decommissioning. However, because the fuel and fuel debris within the RPV is in an extremely highly radioactive environment, it is difficult to observe directly now. Therefore, we developed observation technology utilizing cosmic ray muons that were thought to be an effective non-destructive detection technology, to detect the locations of fuel and fuel debris inside the RPV relatively quickly.

Action items

- Development and verification of detection technology utilizing muon penetration method (verification in Unit 1)

- Verification of detection technology utilizing muon scattering method (verification in Unit 2)

Implementing organizations

Implemented by IRID.

Implementation plan

Source: Progress status of R&D projects and direction for next period

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 26, 2015)) (PDF page 8)

Results & performance by fiscal year

- FY 2017

- Understanding of the location of fuel debris inside the reactor by muon measurement in Fukushima Daiichi Unit 3 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (September 28, 2017)) (PDF)

- Measurement status about understanding of the location of fuel debris inside the reactor by muon measurement in Fukushima Daiichi Unit 3 (Interim report) (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (July 27, 2017)) (PDF)

- Understanding of the location of fuel debris inside the reactor by muon measurement in Fukushima Daiichi Unit 3 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (April 27, 2017)) (PDF)

- FY 2016

- Understanding of the location of fuel debris inside the reactor by muon measurement in Fukushima Daiichi Unit 2 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (July 28, 2016)) (PDF)

- Progress of understanding of the location of fuel debris inside the reactor by muon measurement in Fukushima Daiichi Unit 2 (on-going status) (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (May 26, 2016)) (PDF)

- FY 2015

- Understanding of the location of fuel debris inside the reactor by muon measurement in Fukushima Daiichi Unit 2 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 31, 2016)) (PDF)

- Understanding of the location of fuel debris inside the reactor by muon measurement in Fukushima Daiichi Unit 2 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 17, 2016)) (PDF)

- Completion status at the end of December 2015 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 25, 2016)) (PDF page 49)

- Completion report (Development of fuel debris detection within reactor technology (December 2015)) (IRID) (PDF)

- FY 2014

- Summary of results (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 26, 2015)) (PDF page 5)

- To investigate the position of fuel in reactor using cosmic ray muon, a preparatory test for designing a measuring system was conducted at Fukushima Daiichi NPS (August 20, 2014) (IRID)

Results & performance for individual projects, etc. (Archives)

Switch button

- Development of fuel debris detection within reactor technology, measurement work completion report (flash report) (May 28, 2015) (IRID) (PDF)

- Development of fuel debris condition measurement technology using cosmic rays at Fukushima Daiichi NPS ‐Understanding conditions within RPV in approximately 30cm increments‐ (March 27, 2015) (IRID) (PDF)

- Development of fuel debris detection within reactor technology Unit 1 measurement result report (March 19, 2015) (IRID) (PDF)

- Development of fuel debris detection within reactor technology equipment work completion report (February 26, 2015) (IRID) (PDF)

- Development of fuel debris detection within reactor technology equipment work progress report (January 29, 2015) (IRID) (PDF)

- Development of fuel debris detection within reactor technology progress report (December 25, 2014) (IRID) (PDF)

Completed projects of others

Switch button

Development of technology for non-destructive detection of radioactive materials accumulated inside the Suppression Chamber, etc. (Project of Decommissioning and Contaminated Water Management)

Summary

We developed estimation and measurement methods to estimate the accumulation condition for radioactive materials that might exist inside suppression chambers (S/C), in order to provide necessary information on radioactive materials (whether radioactive materials are necessary or not, etc.) for repair work (water leakage stoppage) on S/C.

Action items

- Create development plan

- Radioactive materials displacement scenarios

- Impact assessment of radioactive materials on water leakage stoppage materials

- Development of technology for detecting radioactive materials

Implementing organizations

Implemented by IRID.

Results & performance by fiscal year

- FY 2014

Inspection inside PCV using small inspection robots (TEPCO effort)

- Results of inspection inside Fukushima Daiichi NPS Unit 3 PCV (October 22, 2015) (TEPCO)

- Document (PDF)

- Images, videos

- Inspection of Unit 3 PCV equipment hatches using small inspection equipment (robots) (November 27, 2015) (TEPCO)

- Document (PDF)

- Images, videos

R&D efforts (related basic and generic research)

<Remote technology for inspection and measurement>

Development of inspection technology (Decommissioning Basic Research: Human resource development program at Tohoku University- Basic research into reliability maintenance of PCV and buildings, etc., and waste processing and disposal, and core human resource development program for decommissioning)

Remote technology (Decommissioning Basic Research: Human resource development program at Tohoku University- Basic research into reliability maintenance of PCV and buildings, etc., and waste processing and disposal, and core human resource development program for decommissioning)

Research on remote operations technology (Decommissioning Basic Research: Human resource development program at University of Tokyo- Comprehensive human resource development for decommissioning based on remote operations technology and nuclide analysis technology) (PDF)

Remote measurement technology (Decommissioning Basic Research: Human resource development program at Tokyo Institute of Technology, - Advancements in skilled human resource development for and basic research on decommissioning engineering) (PDF)

<Fuel debris detection technology related to (muons) >

Development of non-destructive onsite detection technology (JAEA research: Preliminary tests for visualizing structures inside HTTR) (PDF)

Muon radiography (Research at Nagoya University: Inspections inside reactors by muon radiography using nuclear emulsion plates at Fukushima Daiichi NPS Units 2 and 5) (PDF)

Plant investigation, measurement date, and information

Efforts to understand the plant status at each of Units 1 to 3, and for fuel debris retrieval (June 18, 2025)

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment)

- Current Status of Fukushima Daiichi NPS (As of April 24, 2025)

Plant-related parameters

- Plant-related parameters (Summary table) (PDF)

- Temperature parameters (Chart) Real-time data

- Unit 1 Temperature in the RPV (PDF)

- Unit 1 Temperature in the PCV (PDF)

- Unit 2 Temperature in the RPV (PDF)

- Unit 2 Temperature in the PCV (PDF)

- Unit 3 Temperature in the RPV (PDF)

- Unit 3 Temperature in the PCV (PDF)

- Fukushima Daiichi NPS plant data collection at the time of the accident (TEPCO)

- The Great East Japan Earthquake and Current Status of Nuclear Power Station(TEPCO)

- Outline of the plant (IRID) (PDF) only Japanese page

Fukushima Daiichi NPS survey map

Common data presented by Benchmark Study of the Accident at the Fukushima Daiichi Nuclear Power Plant (BSAF) related to accident progression analysis according to OECD/NEA

Information Portal for the Fukushima Daiichi Accident Analysis and Decommissioning Activities

Collection of figures of data on in-core situation (Updated regularly, August 2018)

Collection of links to data on in-core situation ( January 8, 2020)

- Grasping of fuel debris Only Japanese(PDF)

- Stability of fuel debris Only Japanese(PDF)

- Operation safety Only Japanese(PDF)

- Retrieval of fuel debris and others Only Japanese(PDF)

Chronology (Events after the accident, in-core situation, etc.)(Updated regularly, September 2018)

- Chronology of Fukushima Daiichi NPS (Excel File)