Fuel debris retrieval from spent fuel pools

R&D efforts (Application development linked to plant applications and actual use)

Completed projects

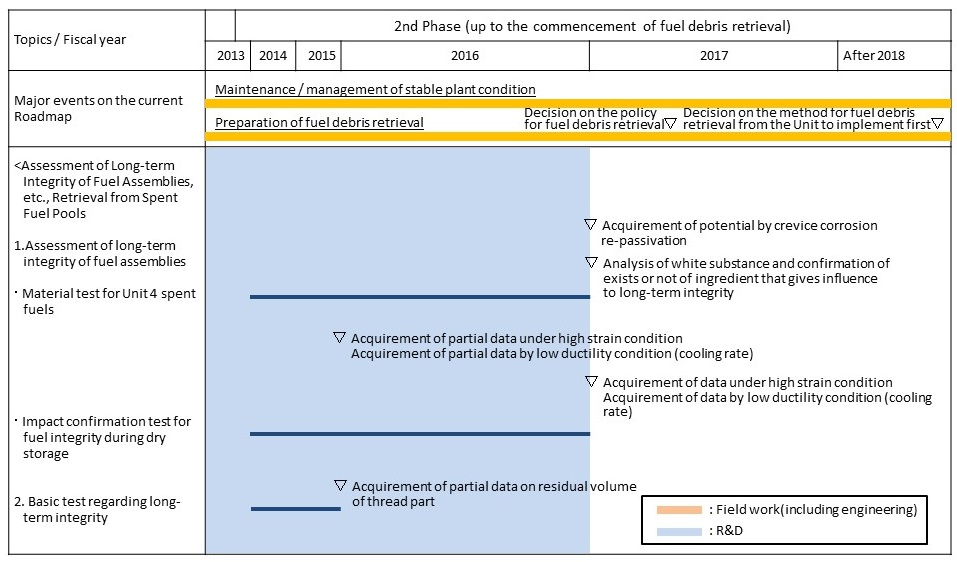

Assessment of Long-term Integrity of Fuel Assemblies, etc., Retrieval from Spent Fuel Pools (Project of Decommissioning and Contaminated Water Management)

Summary

We transported components dismantled from spent fuel of unit 4 to a post-irradiation examination (PIE) facility, and performed material test. Specifically, we performed identification of white sediment on the surface of fuel subassembly, which was detected by visual observation. And we performed verification test for the influence of integrity of the fuel multi-layered with seawater and rubble during strage in dry cask, on the basis of the results of the test, which was conducted by the past fiscal year, about the behavior of hydride precipitates. Also we evaluated the verification method of the integrity during storage in dry cask.

Action items

- Assessment of long-term integrity of fuel assemblies

- Fundamental test regarding long-term integrity

Implementation organization

Implemented by IRID

Implementation plan

Reference:Progress status of R&D projects and direction for next period

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 25, 2016)) (PDF page 34)

Results & performance by fiscal year

- FY 2016

- Completion report (Assessment of long-term integrity of fuel assemblies retrieved from spent fuel pools (July 2017)) (IRID) (PDF)

- Progress as of the end of February, 2017 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF page 27)

- FY 2015

- Interim report (Assessment of long-term integrity of fuel assemblies retrieved from spent fuel pools (April 2016)) (IRID) (PDF)

- Progress as of the end of February, 2016 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 25, 2016)) (PDF page 47)

- Objective and operation result of the assessment of long-term integrity of fuel assemblies retrieved from spent fuel pools (IRID) (PDF)

- FY 2014

- FY 2013

- Assessment of long-term integrity of fuel assemblies retrieved from spent fuel pools (May 29, 2014) (IRID) (PDF)

- Summary of results (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 27, 2014)) (PDF page 3)

- FY 2012

- Summary of results (METI, Council for the Decommissioning of TEPCO’s Fukushima Daiichi (March 28, 2013)) (PDF page 5)

Results, work, etc. by operation (archive)

Switch button

- Test result of spent fuel transferred from spent fuel pool to common pool in the Fukushima Daiichi’s plant No. 4 (December 25, 2014) (IRID, TEPCO) (PDF)

- Test result of spent fuel transferred from spent fuel pool to common pool in the Fukushima Daiichi’s plant No. 4 (November 27, 2014) (IRID, TEPCO) (PDF)

Study of treatment method of damaged fuel, etc. retrieved from the spent fuel pool (Countermeasures for Decommissioning and Contaminated Water Treatment)

Summary

The effects of impurities on corrosion have been evaluated by conducting corrosion test with simulated solution, which was made considering the elements of fission products (FP), to the main equipment used for high-level radioactive liquid waste (such as concentrated high-level waste liquid storage tank, etc.). A transformation of impurities into U/Pu particles when extracted from a compound with FP has also been confirmed. Moreover, glass-property values such as density and glass-transition temperature have been obtained by using sample, which was made based on the high-level radioactive liquid waste water composition.

Implementation items

- Evaluation of corrosion effects of impurities on reprocessing equipment, etc.

- Evaluation of impurities behavior during the operation

- Evaluation of effects of impurities on the conditioned waste

Implementation organization

conducted by IRID

Results and performance by fiscal year

- FY 2014

- FY 2013

R&D efforts (related basic and generic research)

<Updated regularly>

Plant investigation, measurement data, and information

Plant-related parameters (water level, pressure, temperature, etc.)

- Plant-related parameters (Summary table) (PDF)

- Temperature parameters (Chart) Real-time data

- Unit 1 Temperature in the RPV

- Unit 1 Temperature in the PCV

- Unit 2 Temperature in the RPV

- Unit 2 Temperature in the PCV

- Unit 3 Temperature in the RPV

- Unit 3 Temperature in the PCV

- Fukushima Daiichi NPS plant data collected at the time of the accident(TEPCO)

- The Great East Japan Earthquake and Current Status of Nuclear Power Station(TEPCO)

Fukushima Daiichi NPS survey map

Common data presented by Benchmark Study of the Accident at the Fukushima Daiichi Nuclear Power Plant (BSAF) related to accident progression analysis according to OECD/NEA March 2015

Other related information

<Updated regularly>