Ensuring safety for fuel debris retrieval (3) (Construction of containment function)

R&D efforts (Application development linked to plant applications and actual use)

Ongoing projects

Torus room investigation (TEPCO)

- 3D laser scan measurement of Unit 1 reactor building torus room (November 27, 2014) (TEPCO) (PDF)

- 3D laser scan measurement of Unit 1 reactor building torus room (October 30, 2014) (TEPCO) (PDF)

- Regarding camera image of Fukushima Daiichi NPS Unit 1 torus room inspection (first day) (February 21, 2013) (TEPCO) (PDF)

- Fukushima Daiichi NPS Unit 1 torus room inspection (second day) (February 22, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 1 torus room inspection (first day) (February 20, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 1 reactor building torus room interior inspection results (June 27, 2012) (TEPCO) (PDF)

- Implementation of Unit 1 torus room interior inspection (inspection from R/B1 floor pipe penetration) (June 25, 2012) (TEPCO) (PDF)

- Fukushima Daiichi NPS Unit 1 torus room inspection drilling work results (February 14, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Sediment analysis results for Units 1 and 2 torus room stagnant water, and for Units 1 and 2 torus room stagnant water and sediment analysis results (August 29, 2013) (TEPCO) (PDF)

- Fukushima Daiichi NPS Unit 2 torus room inspection (April 12, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 2 torus room inspection drilling work results (March 26, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 2 torus room inspection drilling work results (January 28, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Unit 2 reactor building below ground torus room interior inspection (April 23, 2012) (TEPCO) (PDF)

- Unit 2 reactor building below ground torus room interior inspection (April 19, 2012) (TEPCO)

- Implementation of 3D laser scan measurement of Unit 3 reactor building torus room (December 24, 2015) (TEPCO) (PDF)

- Unit 3 reactor building below ground torus room interior inspection (July 30, 2012) (TEPCO) (PDF)

- Results of Fukushima Daiichi NPS Unit 3 reactor building below ground torus room interior inspection (July 12, 2012) (TEPCO)

- Document (PDF)

- Images, videos

- Making reactor building 3D laser scanning remote, and use of the data (February 26, 2015) (TEPCO) (PDF)

- Implementation of 3D laser scan measurements in Units 1 and 2 reactor buildings (December 26, 2013) (TEPCO) (PDF)

- Torus room site inspection (March 28, 2012) (TEPCO) (PDF)

- Fukushima Daiichi NPS Unit 1 reactor building torus room interior inspection results (June 27, 2012) (TEPCO)

- Document (PDF)

- Images, videos

- Large water tank test results for water leakage stoppage between buildings (March 28, 2012) (TEPCO) (PDF)

Bent pipe inspection (TEPCO)

- Fukushima Daiichi NPS, Unit 1 bent pipe lower portion periphery - Flowing water location flow rate evaluation - (January 30, 2014) (TEPCO) (PDF)

- Fukushima Daiichi NPS, Unit 1 bent pipe lower portion periphery inspection results (November 28, 2013) (TEPCO) (PDF)

- Fukushima Daiichi NPS, Unit 1 bent pipe lower portion periphery inspection results (second day) (November 14, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS, Unit 1 bent pipe lower portion periphery inspection results (first day) (November 13, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 2 bent pipe lower portion periphery inspection results (March 15, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 2 bent pipe lower portion periphery inspection results (March 14, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 2 bent pipe lower portion periphery inspection results (March 6, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 2 bent pipe lower portion periphery inspection results (March 5, 2013) (TEPCO)

- Document (PDF)

- Images, videos

- Fukushima Daiichi NPS Unit 2 bent pipe lower portion periphery inspection results (December 11, 2012) (TEPCO)

- Document (PDF)

- Images, videos

S/C inspection (TEPCO)

- Suppression chamber (S/C) interior water level measurement robot basic technology development restart (January 30, 2014) (TEPCO) (PDF)

- Suppression chamber (S/C) interior water level measurement robot basic technology development results (October 31, 2013) (TEPCO) (PDF)

- Suppression chamber (S/C) interior water level measurement robot basic technology development results (flash report) (September 26, 2013) (TEPCO) (PDF)

- Fukushima Daiichi NPS Unit 2 bent pipe lower portion periphery inspection results (March 13, 2013) (TEPCO)

- Document (PDF)

- Images, videos

Completed projects

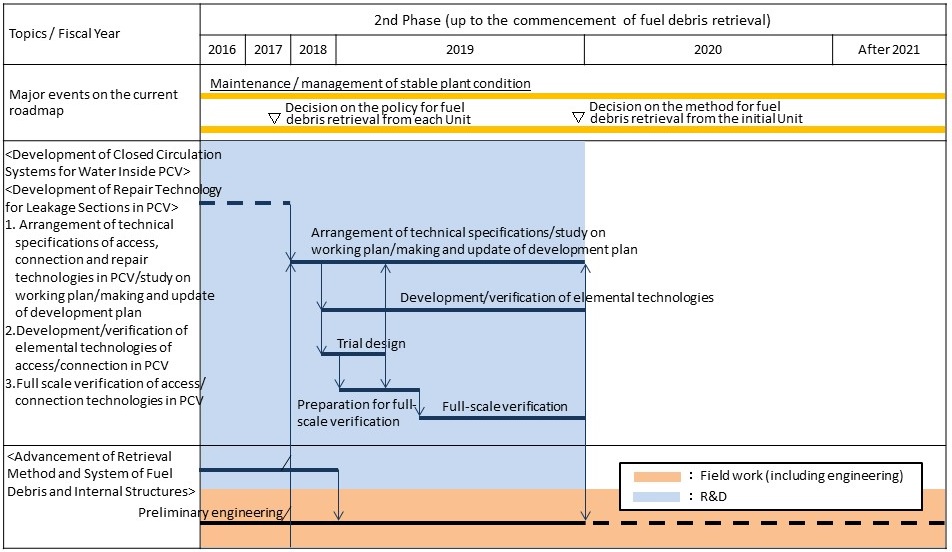

Development of Closed Circulation Systems for Water Inside PCV (Project of Decommissioning and Contaminated Water Management)

Summary

We develop technologies of access, connection and repair in PCV while securing containment function in PCV, in order to build the closed circulation systems for water inside PCV necessary for ensuring safety of retrieval construction of fuel debris.

Action items

- Arrangement of technical specifications of access, connection and repair technologies in PCV/study on working plan/making and update of development plan

- Development/verification of elemental technologies of access/connection in PCV

- Full-scale verification of access/connection technologies in PCV

Implementing organizations

Implemented by IRID.

Implementation plan

Source: FY 2019 Research and Development Plan for Decommissioning

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 28, 2019)) (PDF page 13)

Results & performance by fiscal year

- FY 2018

- Status of progress at the end of February 2019 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 28, 2019)) (PDF page 27)

- Interim report (the first half of FY 2018) (Development of closed circulation systems for water inside PCV (October 19, 2018) (IRID) (PDF)

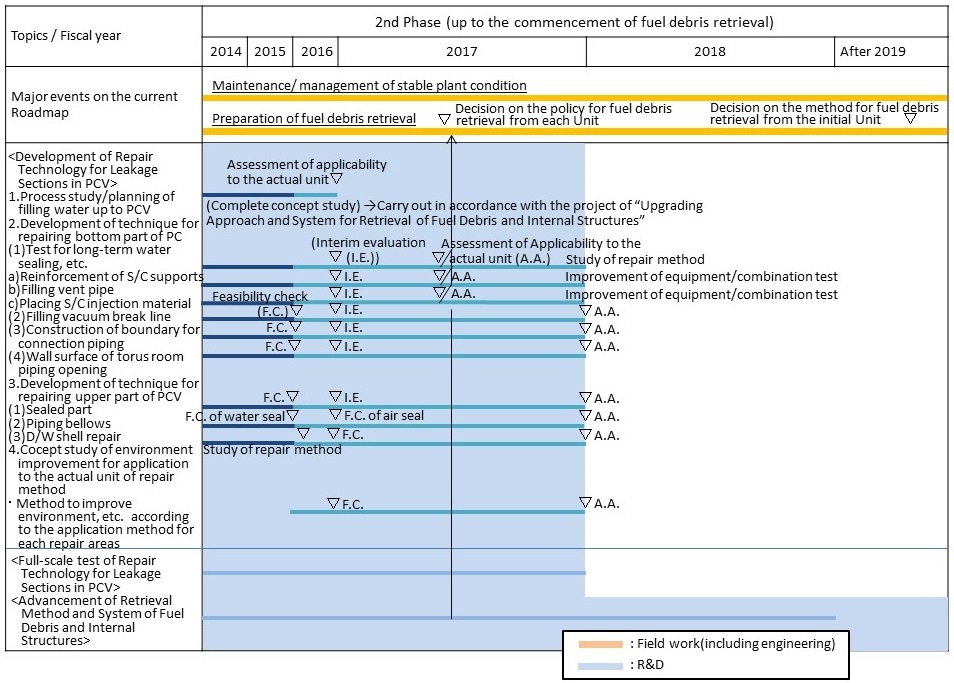

Development of Repair Technology for Leakage Sections in PCV (Project of Decommissioning and Contaminated Water Management)

Summary

We developed technology to build and maintain boundaries for repair and water leakage stoppage of all PCV elements, including reinforcement technology development for suppression chamber supports, examining circulative cooling systems, water leakage stoppage technology for bent pipes, water leakage stoppage technology development for seals, water leakage stoppage technology development for pipe bellows, building boundaries for PCV connection pipes, water leakage stoppage technology for torus room wall pipe penetrations, and D/W shell repair technology. We also created plans for PCV water filling.

Action items

- Process study/planning of filling water up to PCV

- Development of technique for repairing bottom part of PCV

- Technology for reinforcement and water stoppage in S/C and bent pipes

- Technology for water stoppage due to laying vacuum break line

- Connecting piping boundary construction technology

- Development of water stoppage technology for torus room walls with pipe penetration

- Development of technique for repairing upper part of PCV

- Water stoppage technology at seals (equipment hatches)

- Pipe bellows repair technology

- D/W shell repair technology

- Conceptual study of feasibility for practical application of repair method

Implementing organizations

Implemented by IRID.

Implementation plan

Source: Progress status of R&D project and direction for next period

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF page 15)

Results & performance by fiscal year

- FY 2017

- FY 2016/2017 report of results (Development of repair technology for leakage sections in PCV (July 2018)) (IRID) (PDF)

- Status of progress at the end of February 2018 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 1, 2018)) (PDF page 29)

- FY 2016

- Progress status at the end of February 2017 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF page 25)

- Development of repair technology for water leakage sections in PCV testing concrete injection technology for water leak stoppage treatment inside S/C using full-scale mock-up facility (October 15, 2016) (IRID/TOSHIBA)

- FY 2015

- Progress status at the end of February 2016 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 25, 2016)) (PDF page 43)

- Purpose and project results of development of repair and water leakage stoppage technology for leakage points inside the PCV (November 2015) (IRID) (PDF)

- FY 2014

- Summary of results (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 26 2015)) (PDF page 2)

- Development of PCV leakage spot identification technology and repair technology (inspection portion) (October 30, 2014) (PDF)

- Development of PCV leakage spot identification technology and repair technology (repair (water leakage stoppage) portion) (July 31, 2014) (IRID) (PDF)

- Progress status of “PCV lower-section repair technology” test (May 30, 2014) (IRID)

- FY 2013

- FY 2012

- Summary of results (METI, Secretariat of The Council for the Decommissioning of TEPCO’s Fukushima Daiichi (March 28, 2013)) (PDF page 36)

Results & performance for individual projects, etc. (Archives)

Switch button

- Repair and water leakage stoppage technology for PCV lower portion

- Summary of results of trials combining materials that help water stoppage and water leakage stoppage material for lower PCV repair (water leakage stoppage method by burying bent pipes) (May 29, 2014) (IRID) (PDF)

- Summary of progress of (1) tests of materials that help water stoppage and (2) water leakage stoppage tests for lower PCV repair (water leakage stoppage method by burying bent pipes) (March 27, 2014) (IRID) (PDF)

- Seal and bent pipe bellows repair technology

- Water leakage stoppage technology for torus room wall penetrations

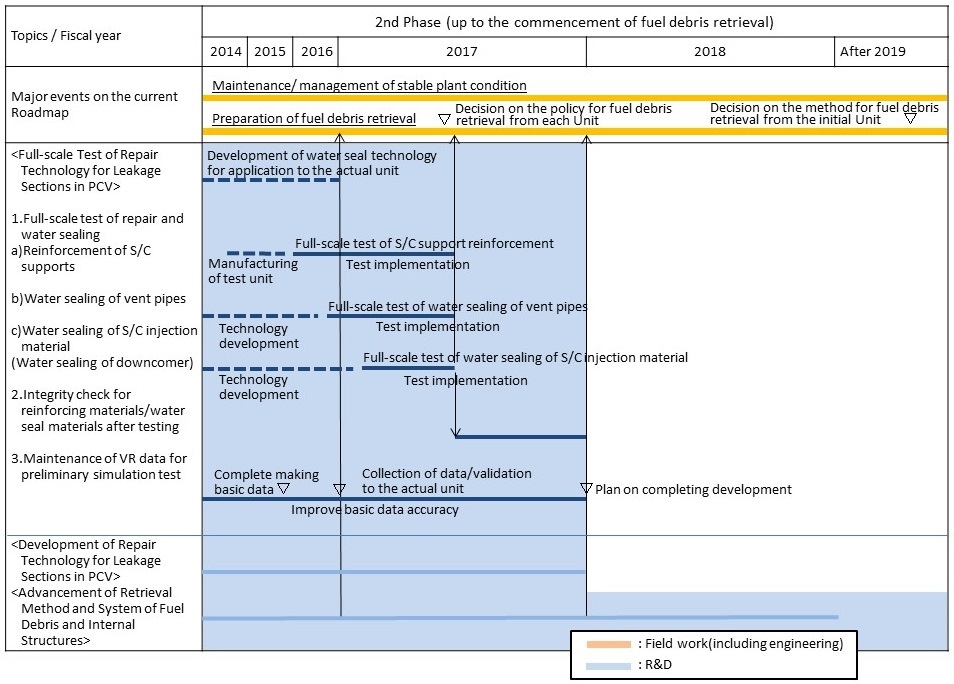

Full-scale Test of Repair Technology for Leakage Sections in PCV (Project of Decommissioning and Contaminated Water Management)

Summary

We used mockup facilities to conduct full-scale tests of machinery and equipment for repair of lower PCV, to verify and assess the applicability and feasibility at Fukushima Daiichi NPS. Also, in order to perform these full-scale tests, we utilized full-size test models that simulate the lower PCV (suppression chamber, bent pipes, etc.), created hypothetical work procedures (drafts) based on plant processes, and confirmed the procedures using that test platform to verify the appropriateness of those procedures. We further took samples of reinforcing material and water leakage stoppage placed on test body through core boring, etc., and performed analysis evaluation of material performance, etc. Then we studied comparisons of the machine operations in full-scale tests to VR system operations, aiming to establish effective and efficient methods for using the VR system.

Action items

- Full-scale test of repair and water sealing

- Integrity check for reinforcing materials after testing and water seal materials

- Maintenance of VR data for preliminary simulation test

Implementing organizations

Implemented by IRID.

Implementation plan

Source: Progress status of R&D project and direction for next period

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF page 16)

Results & performance by fiscal year

- FY 2017

- FY 2017 report of results (final) (Full-scale test of repair technology for leakage sections in PCV (March 2018)) (IRID) (PDF)

- Status of progress at the end of February 2018 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (March 1, 2018)) (PDF page 29)

- Reinforcement of suppression chamber support columns (July 31, 2017) (IRID/Hitachi GE Nuclear Energy)

- Outline of full-scale test of water sealing of PCV (METI Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (June 29, 2017)) (PDF)

- Full-scale testing of water stoppage technology by filling in suppression chamber (S/C) (June 24, 2017) (IRID/Toshiba)

- FY 2016

- Study progress and results (Progress status) (Full-scale test of repair technology for leakage sections in PCV (May 2017)) (IRID) (PDF)

- Progress status at the end of February 2017 (METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 23, 2017)) (PDF page 25)

- Full-scale testing of technology for repairing PCV leakage points full-scale testing of strengthening technology for S/C support columns (November 29, 2016) (IRID/Hitachi GE Nuclear Energy)

- Completion of preparation for full-scale test facility simulating the lower part of the PCV and future test plans (October 13, 2016) (IRID)

- Completed manufacturing a full-scale test device simulated the lower part of the PCV and its test plan (April 20, 2016) (IRID)

- FY 2015

- Completion report (Full-scale test for repair and water leakage stoppage technology for leakage points inside the PCV (March 2016)) (IRID) (PDF)

- Purpose and project results for full-scale test for repair and water leakage stoppage technology for leakage points inside the PCV (March 2016) (IRID) (PDF)

- Progress status as of the end of February 2016 (METI Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment (February 25, 2016)) (PDF page 44)

- FY 2014

Results & performance for individual projects, etc. (Archives)

Switch button

- Torus room investigation

- Results of verification tests of torus room wall inspection equipment in Unit 2 that are in development in the R&D “Development of technologies for repair and identification of leakage points inside the PCV” (October 2015) (TEPCO)

- Document (PDF)

- Images, videos

- Implementation of verification tests of torus room wall inspection equipment in Unit 2 that are in development in the R&D “Development of technologies for repair and identification of leakage points inside the PCV” (June 27, 2014) (TEPCO) (PDF)

- Inspection results (continuing report) for Unit 1 upper S/C and results of inspection of torus room walls in upper S/C (pressure control room) inspection equipment verification tests undergoing development in R&D project “Development of technologies for repair and identification of leakage points inside the PCV” (June 27, 2014) (TEPCO) (PDF)

- Results of inspection of torus room walls in Fukushima Daiichi NPS Unit 1 (June 13, 2014) (TEPCO)

- Document (PDF)

- Images, videos

- Results of verification tests of torus room wall inspection equipment in Unit 2 that are in development in the R&D “Development of technologies for repair and identification of leakage points inside the PCV” (July 31, 2014) (TEPCO) (PDF)

- Fukushima Daiichi NPS Results of inspection of torus room walls in Unit 2 (R&D verification test report) (July 28, 2014) (TEPCO)

- Document (PDF)

- Images, videos

- Implementation of verification tests of torus room wall inspection equipment that are in development in the R&D “Development of technologies for repair and identification of leakage points inside the PCV” (June 27, 2014) (TEPCO) (PDF)

- Utilization of product (inspection etc.), of national projects such as “Development of inspection/repair (water leakage stoppage) technology for water filling PCV” (February 27, 2014) (TEPCO) (PDF)

- S/C inspection

- Fukushima Daiichi NPS Unit 1 S/C (pressure control room) upper portion inspection results (exterior West and South sides) (May 30, 2014) (TEPCO)

- Document (PDF)

- Images, videos

- Implementation of verification test for S/C (pressure control room) upper portion inspection equipment undergoing development in the R&D project “Development of technologies for repair and identification of leakage points inside the PCV” (May 29, 2014) (TEPCO) (PDF)

- Unit 2 S/C (pressure control room) lower portion exterior wall inspection results (September 25, 2014) (TEPCO)

- Document (PDF)

- Images, videos

R&D efforts (related basic and generic research)

Repair technology development (Decommissioning Basic Research: Human resource development program at Tohoku University - Basic research into reliability maintenance of PCV and buildings, etc., and waste processing and disposal, and core human resource development program for decommissioning

Plant investigation, measurement data, and information

Efforts to understand the plant status at each of Units 1 to 3, and for fuel debris retrieval (Updated December 4, 2025)

(METI, Secretariat of the Team for Countermeasures for Decommissioning and Contaminated Water Treatment)

- Current Status of Fukushima Daiichi NPS (As of October 30, 2025)

Plant-related parameters

- Plant-related parameters (Summary table) (PDF)

- Temperature parameters (Chart) Real-time data

- Unit 1 Temperature in the RPV (PDF)

- Unit 1 Temperature in the PCV (PDF)

- Unit 2 Temperature in the RPV (PDF)

- Unit 2 Temperature in the PCV (PDF)

- Unit 3 Temperature in the RPV (PDF)

- Unit 3 Temperature in the PCV (PDF)

- Fukushima Daiichi NPS plant data collected at the time of the accident (TEPCO)

- The Great East Japan Earthquake and Current Status of Nuclear Power Station(TEPCO)

- Outline of the plant (IRID) (PDF) only Japanese page

Fukushima Daiichi NPS survey map

Common data presented by Benchmark Study of the Accident at the Fukushima Daiichi Nuclear Power Plant (BSAF) related to accident progression analysis according to OECD/NEA

Information Portal for the Fukushima Daiichi Accident Analysis and Decommissioning Activities

Collection of figures of data on in-core situation (Updated regularly, August 2018)

Collection of links to data on in-core situation ( January 8, 2020) new

- Grasping of fuel debris Only Japanese(PDF)

- Stability of fuel debris Only Japanese(PDF)

- Operation safety Only Japanese(PDF)

- Retrieval of fuel debris and others Only Japanese(PDF)

Chronology (Events after the accident, in-core situation, etc.) (Updated regularly, September 2018)

- Chronology of Fukushima Daiichi NPS (Excel File)

Other related information

<Updated regularly>